Is there any industry that isn’t being digitised in some capacity or another? Technological advancements make headlines just about every other day. The healthcare sector too is no stranger to the mix of industries interested in digital innovation. Digital health is rapidly picking up the pace when it comes to marrying more efficient medical care with advanced technological systems that enable improvements in multiple areas of medicine.

There is no shortage of challenges in healthcare sectors around the world. One consistent challenge for healthcare researchers and medical technicians is time. It takes a substantial amount of time to develop the solutions necessary to meet the various healthcare needs. It can also take considerable amounts of time to implement these into mainstream healthcare. Often, during this time new healthcare challenges arise. For many in the medical field, new or intensified challenges may feel like a game of ‘catch-up’, or even a never-ending race. This is where the tech industry is figuring out ways it might be able to help.

In some instances, digitising certain systems has begun to provide solutions to time-consuming challenges and is enabling optimum healthcare – thereby saving time, and by extension, money.

Digital ‘printing’ in healthcare is making some inroads too. It’s not such a far-fetched idea that human tissues, including organs can be “printed”. Printers which can ‘dispense’ substances other than good ol’ ink on paper are already in the process of being developed. Medication / drug research and development in this area also appears to be promising.

Could digital printing also offer a solution to the antibiotic resistance crisis? Until recently those dedicated to resolving this issue have felt like they were competing in a life or death race, and one that destructive organisms, like bacteria, were winning. However, if time and money can be saved in the development of new drugs, getting a stronger grip on handling antibiotic resistance may just be possible.

On the 27th of August 2018, HP Inc. announced a rather interesting partnership with the Centers for Disease Control and Prevention (the CDC) – a pilot programme to “print” new antibiotics (i.e. pharmaceutical samples for testing, not actual antibiotic medications in pill form) as a possible means to combat antimicrobial resistant strains (better known as ‘superbugs’) currently associated with antibiotic resistance challenges.

What is antibiotic resistance?

Antibiotic resistance has rapidly become a global health issue. Previously controllable infectious health conditions are now increasingly causing major concerns for medical professionals. ‘Superbugs’ are occurring at an increased rate all over the world. More and more infectious conditions are becoming troublesome to treat, with strains of pathogens resisting the most effective of drugs developed for this purpose.

Antibiotics, also referred to as antimicrobial agents, have been an effective treatment option for more than 70 years. Their use quickly got a handle on infectious disease which threatened the survival of sufferers enormously at the time. Antibiotics have been so effective that they are now widely used, and as it’s come to light, not always correctly. This has led to a growing number of challenges, threatening the level of control medical professionals have over treating various illnesses. Instead of killing off pathogens / microbes, the very same organisms are adapting and gaining the upper hand (i.e. becoming resistant to the medications that once destroyed them and proliferating at an alarmingly higher rate), thus rendering these medications ineffective. And there’s seemingly no contingency plan that is on par with the effectiveness of first-line antibiotics.

How serious is antibiotic resistance?

Disease causing bacterial, viral, fungal and parasitic infections affect millions of individuals worldwide. Many are now unable to be sufficiently treated with the use of first-line antibiotics. Thousands suffer the worst of consequences… Loss of life due to infections which were previously treatable. This is currently a rapidly intensifying concern.

Alternative medications and treatment practices that need to be implemented when antibiotic resistance occurs are costly, and in some instances toxic to patients, resulting in further health complications… the kinds that were previously avoidable. Longer hospital stays, and more frequent medical consultations become necessary, which escalates medical costs. (1) So too does having to use more expensive medications when first-line antibiotics become ineffective.

Foodborne illness (or food poisoning), tuberculosis (TB), gonorrhoea and pneumonia are some infections which are now more challenging to treat than in recent decades and frequently grab global headlines as concerns escalate. All of these are potentially curable or at least treatable conditions or rather they were in the past.

Pathogens are ‘natural evolvers’ too – able to adapt, change and multiply. Thus, there will always be some degree of resistance, but the rate at which organisms are capable of doing so can be slowed down. This was achieved some 70 years ago. It can be done again but developing new classes of antibiotics for specific pathogens takes time.

Health officials are currently tackling the issue of antibiotic resistance as aggressively as they can. Newly developed resistance (microbial growth) is tricky to control, especially when time is of the essence. The CDC is one of the official organisations that is actively collecting and collating data regarding resistant infections so that more effective strategies can be developed to sufficiently prevent further microbial growth. This is necessary in order to slow down the spread of resistant infections while many professionals and researchers are working tirelessly to ensure that new classes of antibiotics are developed for more effective use, thereby enabling improved treatment capabilities.

While there is a need to develop new medication classes, just as important is the encouragement of the correct usage of existing drugs. Inappropriate usage is one of the primary reasons antibiotic resistance is now a major health challenge. Health authorities are continuously encouraging what they call ‘antibiotic stewardship’ by all medical professionals so as to ensure that medication use is appropriate for disease treatment and that the correct classes are therapeutically implemented to best target the specific pathogens that the drugs were designed to combat. Without greater consideration during prescription and behavioural changes when it comes to usage, antibiotic resistance will remain problematic.

Another challenge facing those in the medical field is the ability to test and track the development of antibiotic resistance at the pace at which microbial proliferation takes place. This is where tech corporations may be able to provide a workable solution…

Printing technology, a possible answer to antibiotic challenges?

Joining the battle against antibiotic resistance is the technology organisation, HP Inc. Digitised innovation within major corporations, it seems, is more than capable of lending a helping hand to medical science, and not just in the arena of providing gadgets and ease of convenience products for primary consumer markets.

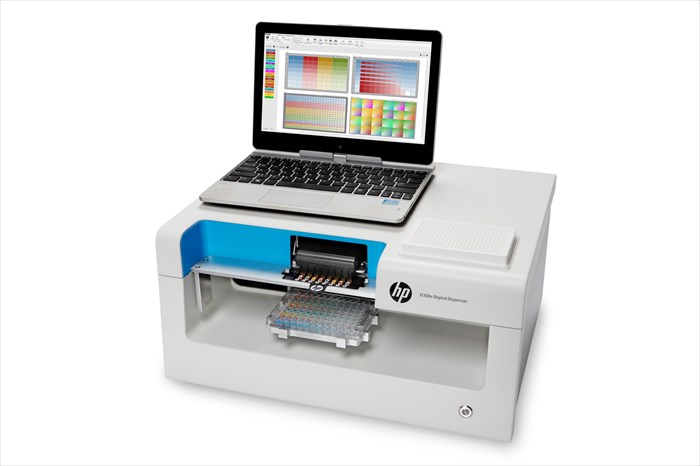

HP Inc. has developed a digital dispenser BioPrinter which has caught the attention of the CDC. The organisation has purchased some of these BioPrinters and agreed to partner up in sharing expertise in order to achieve a common goal.

With the purchase of these HP bioprinters, the CDC is about the launch a pilot programme within four of the organisation’s regional labs in the USA in an effort to tackle part of the antibiotic resistance problem. The regional labs form part of the CDC’s ‘Antibiotic Resistance / AR Lab Network’ - which works to defend against antibiotic resistance. The AR Lab Network was established in 2016 and operates in 50 states, tracking resistance changes and working to determine and implement swift outbreak responses. (2)

The printers will be made available at labs in New York, Wisconsin, Minnesota and Tennessee. Using the inkjet printing technology developed, the programme will test automated laboratory dispensing capabilities in an effort to see if the development of new antibiotic classes can be accelerated.

The announcement of the collaboration and programme launch enables the testing of antibiotics to be conducted at a more local level (i.e. regional) for the very first time. Rapid susceptibility testing (which is used to determine which antibiotics a specific bacteria or fungus is vulnerable to) could potentially deliver better solutions to health departments and clinical environments at an improved pace, which in turn benefits the broader public affected by heightened infection risk.

Many hospitals lack access to susceptibility testing of antimicrobials in order to assess the effectiveness of a particular drug. If all goes well at the four regional labs, these BioPrinters may be a viable option in providing access to susceptibility testing in all clinical environments. This should save substantial amounts of time.

Another time-consuming factor is the process of passing the necessary tested research data and information through administrative approval channels. Often new resistance concerns emerge well before approval processes at the FDA (U.S. Food and Drug Administration) take place. With time being a major concern, technological innovation may just have a pivotal role to play in this regard too.

“To save lives and protect people, it is vital to make technology accessible to hospital labs nationwide. We hope this pilot will help ensure our newest drugs last longer and put gold-standard lab results in healthcare providers’ hands faster,” says Jean Patel, the CDC’s science team lead at the Antibiotic Resistance Coordination and Strategy Unit.

The HP D300e Digital Dispenser BioPrinter is set to assist in speeding up the susceptibility testing process at the selected regional labs. Gold standard test plates can now be tested within a matter of a few minutes at a time as opposed to hours or even days as is currently the case with similar testing processes. The testing process may very well help to avoid the future overutilization of antibiotics, which plays a major role in resistance challenges, in addition to underutilisation and misutilisation issues wherein these drugs are not available to patients or are used inappropriately causing health complications and side-effects.

The BioPrinter offers users in research settings the opportunity to achieve more accurate testing outcomes at a faster pace. The efficiently set up software “prints” small molecules and biomolecules of DMSO (dimethyl sulfoxide) and aqueous drug solution combinations in picolitre and microlitre volumes enabling more reliable genomic, proteomic and medication discovery research. The software is programmed to allow for:

- Triplicate titrations (i.e. a quantitative chemical analysis)

- Complex medication synergy

- Randomised testing design

- Miniaturised qPCR assay (i.e. a quantitative polymerase chain reaction analysis available in real-time)

The BioPrinter is equipped with two dispense-head cassettes. One can dispense up to 8 DMSO and aqueous fluid solutions. The other can dispense up to 4 normalisation fluid solutions, as well as master mix and primer additions which may be required.

The system allows for a broad range of low-volume dispensing applications to be conducted including cell-based and biochemical assays, drug combination assessments, enzyme profiling, antibody therapy analysis, synthetic biology and primary and secondary screening, among others.

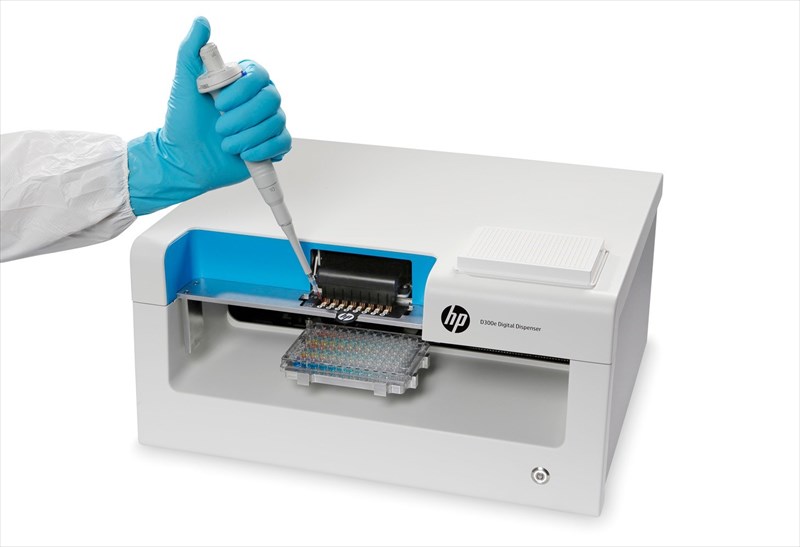

The software is set up in an efficient manner that allows for complex plate protocols to be easily programmed and run. Concentrated microlitre samples are loaded directly into the dispenser cassette, after which a series of doses are created, accurately and rapidly dispensing non-contact droplets into the plates below. This is effective for dose-response studies and independent titration analysis. Exploring potent molecules is also valuable in that improved insights can be achieved.

The first compound solution (which is red) is loaded and directly dispensed across a concentration range of rows. The second compound solution (which is blue) is loaded and directly dispensed in columns. This creates a valuable set of combination doses for analysis.

Direct dispensing allows for the elimination of serial dilution (i.e. dilution due to multiple processing steps) from laboratory research workflow (manual pipetting - normally done by hand) – The HP system can use up to 10 times less solution this way. Fewer dilution steps means reduced set-up requirements and accompanying technician fatigue and repetitive motion strain. Once-off dispensing eliminates these types of time-consuming constraints in the testing process.

An hour of software training is all that is required for researchers to use the BioPrinter system. The setup of plate protocols and run time (i.e. dispensing / ‘printing’ of samples) can then be done within a space of an hour. Once a plate protocol is run, an assay plate is ready within a matter of minutes, allowing for analysis and follow-up work to be completed much quicker as well. This in turn helps to reduce expenditure too. Users are already finding that the results are not only rapid, efficient and accurate but also consistent.

The pilot programme will officially be implemented during the first quarter of 2019. The CDC aims to prioritise resistant bacteria, especially pan-resistant pathogens (i.e. organisms which are most resistant to first-line antibiotic medications). During the programme process, both HP Inc. and the CDC will coordinate their expertise respectively to ensure the refinement of the BioPrinter system and determine the best ways to implement a larger rollout of the technology to more AR labs in the network.

“We are honoured to collaborate with the CDC and others in our commitment to innovate solutions that can enhance drug susceptibility testing, ultimately improving patient health,” says HP’s Vice President and General Manager (Specialty Printing Systems), Annette Friskopp.

It is the CDC’s hope that this combined effort could soon see the testing process reach hospital providers, boosting laboratory testing productivity, which will in turn be able to better provide access to improved quality antibiotics where it is most needed within patient care, much sooner.

References:

1. World Health Organization. 5 February 2018. Antibiotic Resistance - Fact Sheet: http://www.who.int/en/news-room/fact-sheets/detail/antibiotic-resistance [Accessed 04.09.2018]

2. Centers for Disease Control and Prevention. 30 March 2018. Antibiotic Resistance (AR) Lab Network: https://www.cdc.gov/drugresistance/solutions-initiative/ar-lab-networks.html [Accessed 04.09.2018]